Recommended Specifications:

2.0mm, 0.30mm

2.5mm, 0.50mm

3.0mm, 0.50mm.

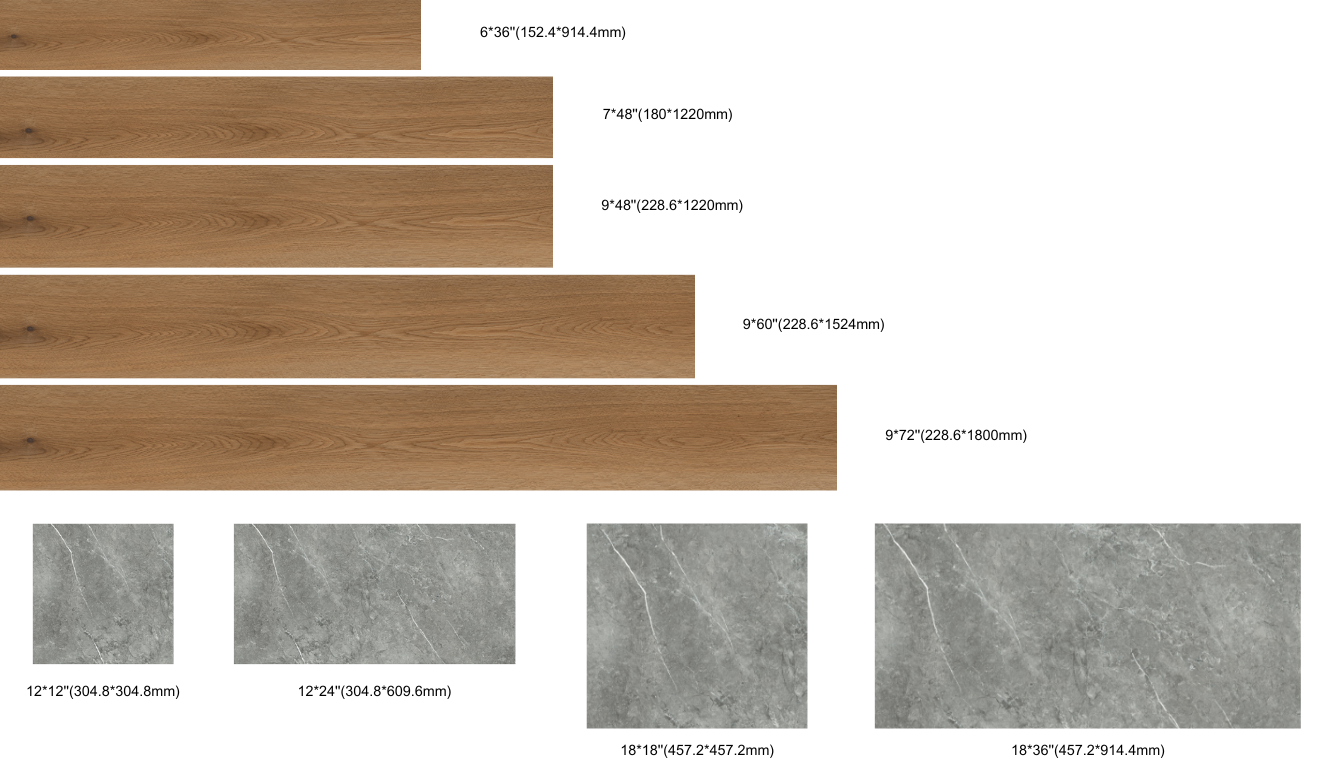

Available Sizes: 6*36'', 7*48'', 9*48'', 9*60''

Luxury vinyl tiles are commonly made from multiple layers of PVC vinyl. The PVC is mixed with various compounds to affect the hardness. These multiple sheets of PVC vinyl are carefully compressed by a rolling process, suspended in a liquid. This is then dried through an application of heat and air to produce tough sheets of vinyl. The top layer can also feature an embossed finish, with manufacturers being able to add realism to the top layer by adding a layer of depth to help mimic the grooves found in stone or wood. LVT could be installed with glues.

Recommended Specifications:

2.0mm, 0.30mm

2.5mm, 0.50mm

3.0mm, 0.50mm.

Available Sizes: 6*36'', 7*48'', 9*48'', 9*60''

Product Structure

Product Structure

Why Choose LVT Dry Back?

Why Choose LVT Dry Back?

ALMOST INDESTRUCTIBLE

Today, vinyl is almost indestructible, making LVT a popular choice for high traffic areas. The outer layer of the vinyl consists of PVC, which protects the material and generally has a non-slip finish.

RESISTANT TO MOISTURE AND DAMPNESS

LVT flooring is 100% water-resistant and so particularly suited to wet and humid areas like kitchens and bathrooms. So no need to worry about water leaks or faulty appliances. The outer layer is also treated to be anti-bacterial for additional protection.

LITTLE MAINTENANCE

Vinyl flooring will only require regular sweeping and a weekly mop (avoid abrasive detergents).

EASY TO LAY

There is no need for professional installation. Anyone with a measuring tape and a knife can lay LVT flooring. It can be easily cut, making it especially suitable for bathrooms where tiles need to be shaped around bathroom artefact.

VALUE FOR MONEY

Costing a fraction of the materials they imitate, LVT flooring will last and last. The higher-end products tend to have a thicker stability layer.

Specification

Specification| Characteristics | Test | LVT Dry Back |

| Classification | EN685 | 21~44 |

| Dimensions | ISO24341 | 180 * 1220 mm |

| Straightness / Squareness | ISO24342 | ≤0.25mm |

| Thickness | ISO24346 | 3mm ± 0.13mm |

| Wear Layer Thickness | ISO24340 | 0.55mm (+13%/ -10% ) |

| Weight | EN430 | 5.89kg/㎡ 5.85kg/㎡ (for tile) |

| Abrasion Resistance | EN660:part-1 | Group T:≤0.08mm |

| Residual Indentation | ISO24343-1 | ≤0.10mm |

| Chemical Resistance | EN438 | Grade 5 |

| Fire Resistance | EN13501 / ISO9239-1 | Class BFLs1(B1) |

| Dimensional Stability | ISO23999 | ≤0.12% |

| Color Fastness | ISO 105-B02:1994 | ≥Grade 6 |

| Water Resistance | EN317 | 0% Swelling |

| Slip Resistance | AS4586 / DIN 51130 | R10 |

| Formaldehyde Emission | EN717-1 | E1 |

| Curving | ISO23999 | ≤1.2mm |

| Peel Resistance | ISO24345 | ≥75N/5cm |

| Anti-scratchs | —— | ≥2500g |

| Acoustic Performance | EN ISO 717-2 | △Lw=15 dB |

| Cigarette burn resistance | EN438-2 | Class 3 |

| Flexibility | ISO24344 | 20mm |

| Castor Chair | ISO4918 | After 25 000 cycles, no delamination shall occur. |

Sizes

Sizes