Recommended Specifications:

3.5mm, 0.30mm.

4.0mm, 0.50mm.

5.0mm, 0.50mm

6.0mm, 0.50mm.

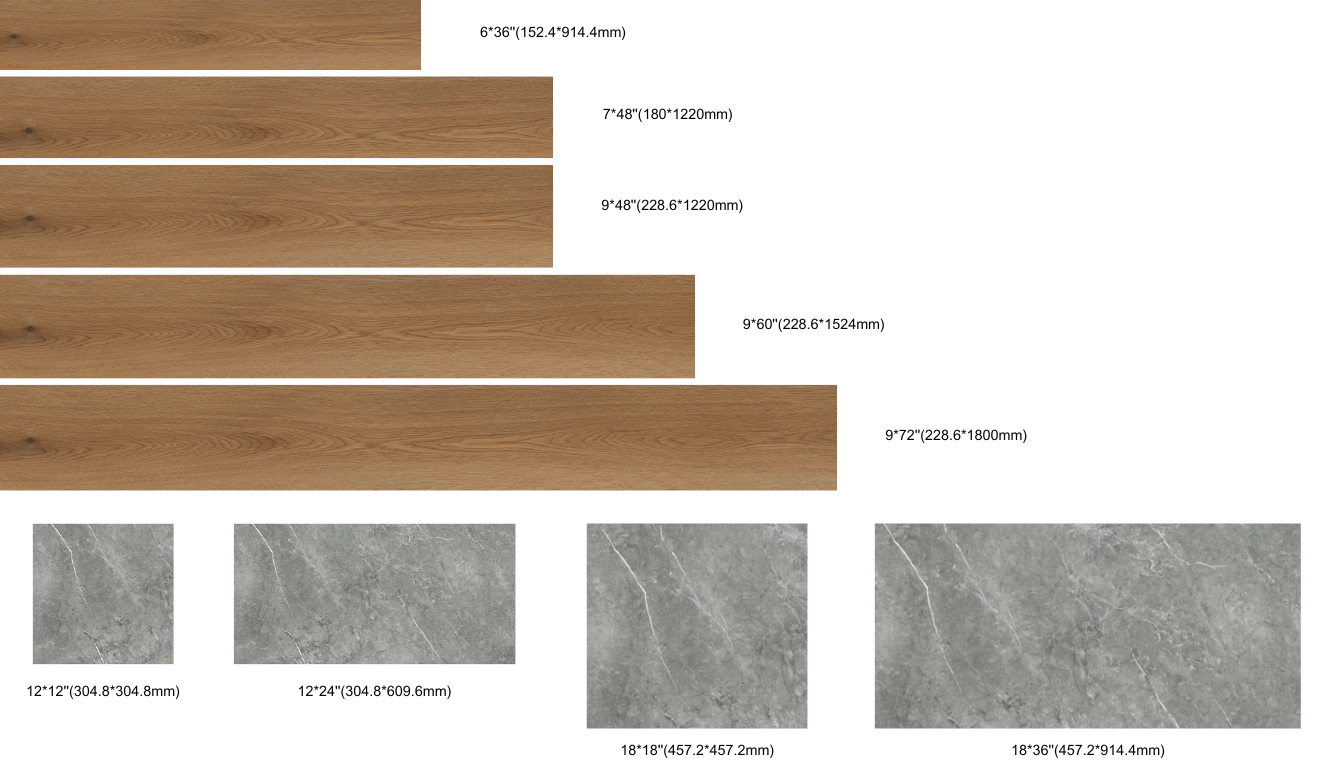

Available Sizes: 6*36'', 7*48'', 9*48'', 9*60'', 9*72''

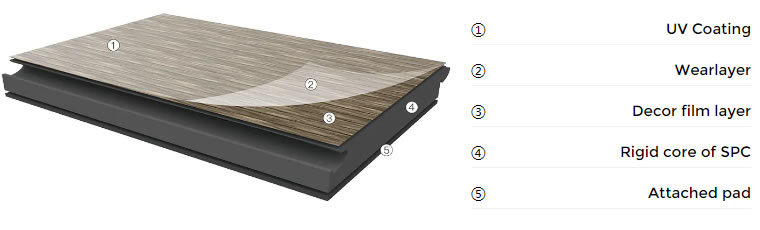

Solid Polymeric Core Flooring, also called Rigid Vinyl Plank(RVP), or hybrid flooring. It is an upgraded version of LVT. SPC flooring consists of several layers: UV coating, wear layer, SPC print layer, SPC core, and a balanced layer. The backing can vary thanks to a variety of options including EVA, corkwood, and IXPE foam.

Recommended Specifications:

3.5mm, 0.30mm.

4.0mm, 0.50mm.

5.0mm, 0.50mm

6.0mm, 0.50mm.

Available Sizes: 6*36'', 7*48'', 9*48'', 9*60'', 9*72''

Product Structure

Product Structure

Why Choose SPC?

Why Choose SPC?

DURABILITY

SPC flooring has a robust, compact composition which contains natural limestone powder, polyvinyl chloride, and stabilizers which makes the material a durable companion against every day foot traffic, both in commercial and residential areas.

HIGH IMPACT RESISTANCE

The floor bears most of the impact and traffic from pets, kids' toys, furniture, heavy objects, and people. Thus, it is susceptible to scratches and dents. Good thing is, SPC flooring is highly resistant to all these because of its material composition.

WATERPROOF

SPC flooring is ideal in all interior floors, including areas where there is continuous contact with water such as bathrooms, kitchens, and laundry areas. Having a waterproof material for flooring limits the proliferation of dirt and bacteria, prevents the floor from warping or deformation, and lessens time allotted for cleaning and maintenance.

WEAR RESISTANCE

SPC flooring is pet, kids and business establishment- friendly, because it does not easily wear nor fade, even for a long time. This is a good option for residential homeowners, pet owners and business establishments alike, who need their floor resistant to scratches and stains, and live on little to zero upkeep.

FIRE RESISTANCE

Floors occupy the majority of the space in our home, thus the flooring material’s reaction to fire must be greatly considered. SPC flooring is made up of materials that do not speed up the propagation of the fire and do not ignite in low temperatures, so it is safe for both commercial and residential areas.

CHEMICAL RESISTANCE

Chemical resistant flooring like SPC keeps the material from fading color, warping, and free from proliferation of bacteria, even when spilled on, or placed in contact with chemicals.

UV RESISTANCE

The UV resistant layer of the SPC flooring panel keeps the material from fading even when placed in floors near doors and windows, or in places in direct contact to the sun. This makes your space look new, seamless, and unblemished against high temperatures.

SILENT UNDERLAYMENT

The IXPE underlayment provides proper sound insulation and cushioning. This distinct feature of SPC makes it a good option for residential areas where a quiet and peaceful atmosphere is needed. More than noise cancellation, the foam underneath the panel also increases walking comfort for the users.

EASY INSTALLATION

For a quick, convenient, and easy installation, SPC flooring is a must for you. SPC flooring requires no tools or adhesives to stick to the floors, nor does it require expansion joints or transition profiles to have a seamless finish. SPC flooring employs a click-lock system for a cleaner-looking flooring. To install, use a rubber mallet to help in securing the panels with each other. Uninstalling SPC is also just as easy as installing it, for easier and faster replacement or renovation.

EASY TO CLEAN AND MAINTAIN

SPC floors repel stains and spills. You do not need extensive general cleaning nor hire professional help to make the floor look new. To clean, it is enough to use simple cleaning tools like damp cloth and mild washers.

Specification

Specification| Characteristics | Test | SPC Online |

| Classification | EN685 | 21~44 |

| Dimensions | ISO24341 | 180 * 1220 mm |

| Straightness / Squareness | ISO24342 | ≤0.25mm |

| Thickness | ISO24346 | 5mm ± 0.13mm |

| Wear Layer Thickness | ISO24340 | 0.55mm (+13%/ -10% ) |

| Weight | EN430 | 7.8kg/㎡ |

| Abrasion Resistance | EN660:part-1 | Group T:≤0.08mm |

| Residual Indentation | ISO24343-1 | ≤0.10mm |

| Chemical Resistance | EN438 | Grade 5 |

| Fire Resistance | EN13501 / ISO9239-1 | Class BFLs1(B1) |

| Dimensional Stability | ISO23999 | ≤0.12% |

| Color Fastness | ISO 105-B02:1994 | ≥Grade 6 |

| Water Resistance | EN317 | 0% Swelling |

| Slip Resistance | AS4586 / DIN 51130 | R10 |

| Formaldehyde Emission | EN717-1 | E1 |

| Curving | ISO23999 | ≤1.2mm |

| Peel Resistance | ISO24345 | ≥75N/5cm |

| Anti-scratchs | —— | ≥2500g |

| Acoustic Performance | EN ISO 717-2 | △Lw=15 dB |

| Cigarette burn resistance | EN438-2 | Class 3 |

| Locking Strength | ISO24334 | ≥1200N/50m |

| Flexibility | ISO24344 | 20mm |

| Impact Resistance | EN1534 | 7.4 Kgf/mm³ |

| Castor Chair | ISO4918 | After 25 000 cycles, no delamination shall occur. |

Sizes

Sizes